Powder and bulk weighing systems provide innumerable benefits for almost every industry available. Commodities such as food and drink, chemicals, plastics, paint, fertilizers, minerals, and concrete products are a few of the goods stored, processed, and inventoried within a bulk weighing system. The capability to process massive amounts of these materials expediently and efficiently is an immense windfall for our society, keeping goods readily flowing and accessible at a moment’s notice. When one thinks of processing large amounts of materials, weight indicators rarely come to mind. These unheralded pieces of equipment can provide some of the most important functions for bulk weighing systems, acting as the “brain” of the operation in some instances, or integrating with existing software to complete certain weighing tasks. Without some of the processes organized by indicators’ logic and control systems, bulk weighing would be a much more laborious and time-intensive endeavor, resulting in slower and more expensive production processing.

Indicator programming can cover a great breadth of machine logic and provide simple solutions to complex, synchronized processes. The following sections will detail some of the more common options available to bulk processing manufacturers and the description of each program function.

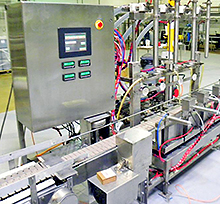

Programmable Logic Controllers (PLC)

Programmable Logic Controllers are simply systems of regulation controlled by programming logic that oversee industrial control operations. This type of system is utilized in industries such as oil refineries, manufacturing lines, and conveyor systems. Because of their capability to integrate with systems of mass production with high accuracy and efficiency, PLCs are highly economical.

Indicators that have this capability usually have RS232 or USB serial communication protocols, though some are more advanced and have Ethernet or Modbus connectivity. Programmable inputs and outputs are usually included to allow even more flexibility.

Basic Tank Inventory

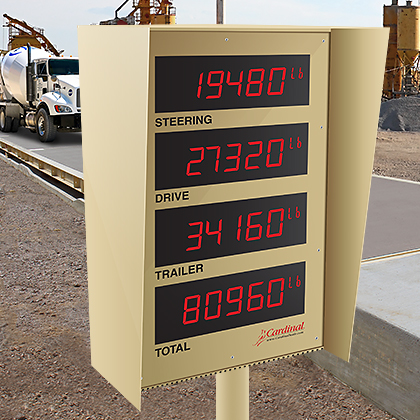

A basic tank inventory monitoring system observes product levels in a hopper or tanking system. This is noted by a remote display or by using a check weigh feature controlled by an indicator. Monitoring a tank inventory is valuable to gauge availability of any given product in an automation system, whether it be a single ingredient or a more-complex injection system controlling multiple ingredients.

Digital Fill Control (DFC)

Digital fill control deals with single-ingredient operations. This system supports single or dual-speed relay control outputs which orchestrate material filling and discharge automatically. Indicators with digital fill control allow for setting target and trim weights to be entered at the beginning of the cycle. The required target weight that’s established completes the cycle for the fill operation. Digital fill control is best incorporated in operations handling agricultural items such as seed, molasses, and feed, or industrial items such as cement or slurry.

Batching

A batching system has the capability to measure any filling or discharge of material, (i.e. either an increase or loss), utilizing a weight system to ration a discrete and separate amount of each material. Batchers are best suited for blending or mixing operations. Multiple sources can feed a common hopper, and if this is the case, it is prudent to feed the hopper sequentially in order for multiple ingredients to be measured individually. Batching speed can be a concern for some systems, so a “loss of weight system” can be utilized to meter material parsed out of a respective storage bin. This loss of weight system allows for materials to be simultaneously fed into a common hopper, mixer, or processing apparatus. A great advantage of a loss of weight system is the ability to measure ingredients or materials that are disparate in size.

Indicators with the capability to control batching operations typically possess certain features. Sequencers are utilized to coordinate gate operations for batches of ingredients. Trim weights are weight values used by the operator to compensate for material that will continue to flow after a “stop” action has been initiated. Removing material can be enabled automatically, manually, or from a remote control. Most indicators also come equipped with a decumulative operation. In a decumulative batching operation, the weigh hopper is filled first until the required amount of material has been placed in the hopper. When the operation is started, the material is dumped until the proper amount has been discharged.

Continuous Bulk Weigh

The continuous weighing—also referred to as gravimetric feeding—of a dry bulk solid is normally completed either by continuous belt feeding or loss of weight feeding. Continuous bulk weighing is usually designed to control the flow of material from an upper garner into a lower garner or surge bin. Loss of weight feeders operate by parsing material out of a storage container, using a weight signal feedback to establish a rate over time. Once a low level is reached in a storage bin, the unit must be refilled. Materials that have a coarse, granular consistency would be best suited to a weigh belt feeder to meter material continuously out of the storage apparatus. There is no refill cycle for this system, since the belt is infinitely pulling material and weighing it. The belt in a continuous weigh system incorporates the belt speed with the weight on a belt section to control the rate.

To complete the tasks mandatory for a continuous bulk weighing operation, there are certain attributes within the indicator that will be necessary. Most bulk weighing systems will have a zero limit, trim adjust, fill alarms and timers, maintenance features, and presets. A printing option is required for an operation controlled by FGIS or NTEP regulatory bodies. Each of these functions performs an important utility within the system.

The Zero Tolerance and Trim Adjust functions are standard for continuous bulk weighing. The Zero Tolerance function sets a hopper weight limit; this limit is important since it precludes a new fill from starting if the hopper weight is not near zero. Trim Adjust functions permit gating to close within a certain poundage amount, allowing for a preprogrammed amount of material “in the air” to land in the hopper, reaching the desired weight limitation. Trim Adjust functions can be manual or automatic depending on material consistency. Commodities that are more fluid allow for using automatic settings, whereas for materials with “chunkier” consistencies manual settings tend to be a more viable option.

Timer Functions are time delays to guard against material outages and incorrect readings. The Fill Alarms and Dump Time functions are set to a value that, if exceeded, will set off an output alarm to alert operators of a material flow problem. Fill Settle and Extend Dump timer functions allow for the hopper of a given system to settle before a draft of material is completed.

In conclusion, some weight indicators contain valuable programming options and logic to assist automation processes in increasing speed, accuracy, and consistency. Understanding the available options can be critical to meeting production goals or meeting specific industrial needs. Utilizing the correct indicator and its accompanying functions will provide your business with the best prospect to increase profits and viability in the current market.

Contact:

Cardinal Scale Manufacturing Co.

203 East Daugherty St.

Webb City, MO 64870

(800) 441-4237

cardinal@cardet.com

Leave a Comment

Your email address will not be published. Required fields are marked *